At Granite & Marble Specialties, we believe that technology is essential to creating the highest quality stone products. We use a variety of state-of-the-art technologies in our fabrication process, from computerized design and cutting to laser polishing and edge profiling. This allows us to achieve a level of precision and accuracy that is simply not possible with traditional methods.

Here are some of the specific ways we use technology at Granite & Marble Specialties:

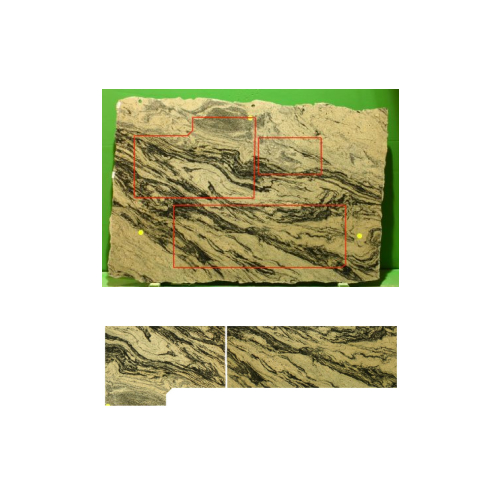

- Computerized design (CAD): We use CAD software to create precise digital templates for countertops, backsplashes, and other stone products. This allows us to visualize the finished product and make any necessary adjustments before fabrication begins.

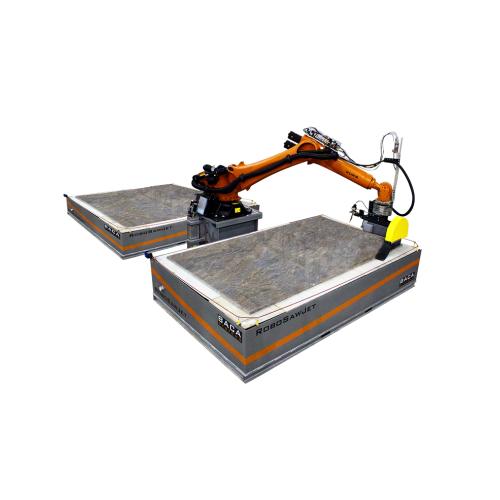

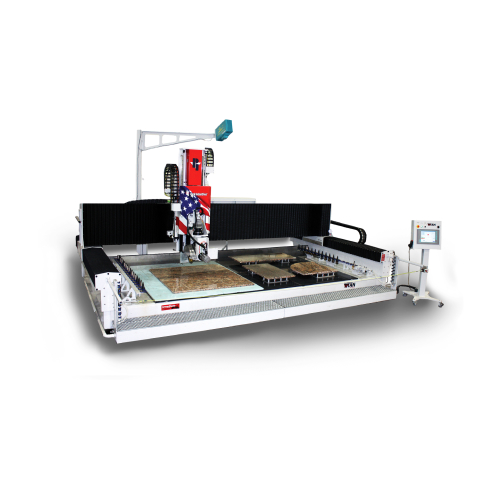

- Computerized numerical control (CNC): Our CNC machines use CAD templates to cut and shape your stone products with incredible accuracy and precision. This ensures that your pieces will fit perfectly together and create a seamless finish.

- Waterjet cutting: Waterjet cutting is a state-of-the-art technology that uses a high-pressure jet of water to cut through stone with great precision. We use waterjet cutting to create intricate designs and patterns that would be impossible to achieve with traditional methods.

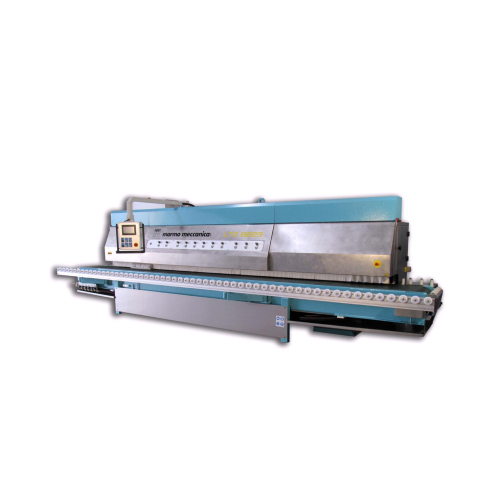

- Laser polishing: Laser polishing is a new and innovative technology that uses lasers to polish stone to a high shine. This process is much faster and more efficient than traditional polishing methods, and it produces a superior finish.

- Edge profiling: Edge profiling is the process of shaping the edges of your stone countertops and other products. We offer a variety of edge profiles to choose from, and our CNC machines can create even the most complex profiles with ease.

Fall Special Offer

Fall Special Offer